COOLING METHODS FOR GARMENT FACTORIES

Factory cooling is currently an issue that receives attention from many garment companies, due to the hot, dusty and poorly ventilated operating environment in the factory, so the design and installation of a factory cooling system is extremely important. Choosing a unit specializing in the construction of this system is also an issue that investors need to pay attention to. With 10 years of experience in the refrigeration industry, Sao Viet Air Conditioning Technology Joint Stock Company has signed many contracts to design and install cooling systems for many factories, including garment factories. For example: Nomura - Fotranco Co., Ltd. Address: 174/226 Le Lai Street, May Chai Ward, Ngo Quyen, Hai Phong. PIT VINA Co., Ltd. Address: An Hung, An Hung Commune, An Duong District, Hai Phong. GUO XIANG Co., Ltd. Address: Nomura Hai Phong Industrial Park... Ensuring to bring you the best service

.jpg)

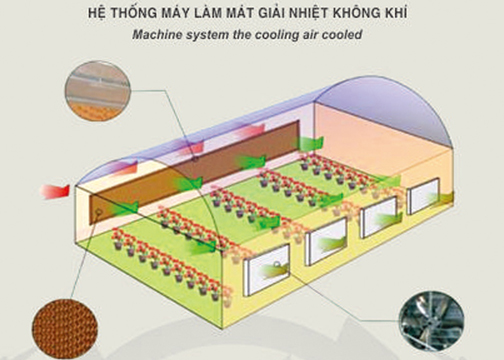

Normally, garment factories apply the method of cooling by steam through cooling fans and cooling pads. With this method, the system includes the following equipment and components:

1. Factory cooling machine

2. V4 or V5 steel cooler bracket

3. Pipe system leading into the factory

4. Air vent to distribute air to the location that needs cooling

5. PVC pipe for water supply and drainage for the cooler

6. Circulating water tank for the entire system (with insulation)

7. Water cooling equipment cluster ensures water temperature < 22oC – 25oC

8. Electrical system equipment and supplies for cooling machines

The evaporative cooler can be placed behind the wall of the factory or on the roof. When installing, the contractor can design the cooler to be placed in a place suitable for the capacity and area of the factory or can be placed in a place where many workers sit and work. This will help save investment costs, help the system operate effectively and reduce electricity consumption costs.

System air duct in Hai Phong

The factory cooling machine operates, part of the water will evaporate into the air to reduce the temperature, the rest flows down along the cooling plates to the water tank in the machine to continue a new cycle. There is a note (if choosing a high-performance cooling system, the cooling temperature is less dependent on the external environment and circulating water, thus saving the amount of water used, the circulating water in the system always changes to help the system operate effectively, creating a cleaner and cooler air flow into the factory)

Based on the operating principle of the evaporative cooling system, we can know the effects of the system on the factory:

The cooling system consists of 4 cooling pads arranged vertically around the inside of the machine. When water is supplied, it will flow into a layer on the surface of the Pads. The fan blades rotate to suck the surrounding air through the Pads and blow it into the space that needs to be cooled. The air passes through the water curtain to evaporate the water. At that time, the air temperature is reduced by 5-7oC depending on the conditions and design. In special cases, it can be reduced to 10oC and the air is blown into the locations that need to be cooled through the duct system and air vents.

Details of the operation of the evaporative cooling system see here

If you need to install a factory ventilation system, please contact:

Contact information:

Phone: 02253 567 618

Hotline: Mr. Viet 0983 260 704

Email: dieuhoasaoviet@gmail.com

Facebook: https://www.facebook.com/dieuhoasaoviet68/